SOLUTIONS

Oil & Gas

Gas shells, cylindrical and toroidal fuel tanks. Our solutions allow to produce, within the same system, tanks of different sizes, thus optimizing the set-up times and the management of the machinery with consequent benefits on the performance and cycle times.

Ventilation

Measurable benefits in the technology of the die and in the automation used, which make it possible to reduce the number of passages involved in the process as well as the scrap, with a consequent result in terms of cost-cutting and space reduction of the industrial plant involved. Our turnkey automatic line is capable of producing ventilation fittings such as ducts, angles, reducers and «T» pieces.

Cookware

We offer production solutions for the manufacturing of pots, lids, pans and tins that allow optimizing the deep-drawing operations by adjusting the speed, the force and the strokes of the blankholder and the extractors. Operations as such are particularly important when materials like stainless steel or multy-layer steel are involved and also when a high quality of the piece produced, free from defects, needs to be achieved.

Kitchen system

We design and develop turnkey lines for stainless steel sinks, hoods, components for ovens and cooker tops, with the possibility to provide automatic systems of table change and die clamping, line interface and teleservice provision.

Heating & Cooling

OMERA is a major worldwide player with its turnkey production lines for the manufacture of expansion tanks, water heaters, heat pumps and coolers. We offer productive solutions with a high degree of flexibility and with the possibility of interconnecting with the factory system.

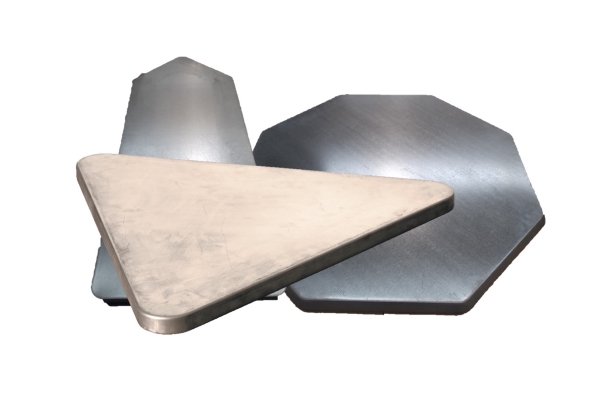

Road signs

We are present in the market with an innovative production of polygonal road signs. Starting from the blank, thanks to our CNC trimming-beading machines, a world-leading product, we offer the possibility to perform steel and aluminium road signs of any size.